bursting strength test fabric|how to measure bursting strength : makers (In other word) Fabric bursting strength test is an alternative method of measuring strength in which the material is stressed in all direction at the same time and is . Resultado da 5 de dez. de 2023 · SuaBet é Confiável? Essa empresa é uma opção extremamente confiável para quem está querendo realizar apostas na .

{plog:ftitle_list}

Resultado da 6 dias atrás · Resultados de Cupón diario Miércoles 28 de Febrero de 2024: 67005 Serie: 027. otros sorteos. ver premios. Resultados de Cuponazo de .

(In other word) Fabric bursting strength test is an alternative method of measuring strength in which the material is stressed in all direction at the same time and is .Textile Learner is a reference guide for textile engineering. It helps to update .What is the Fabric Bursting Strength Test? The burst strength of the fabric is typically determined through a standardized test method called the “bursting strength test.” During this test, a defined pressure is applied to a fabric . 1.1 This test method describes the measurement for bursting strength of woven and knitted textiles taken from rolls of fabric or fabric taken from garments. Note 1: For the measurement of bursting strength with a hydraulic or pneumatic machine, refer to .

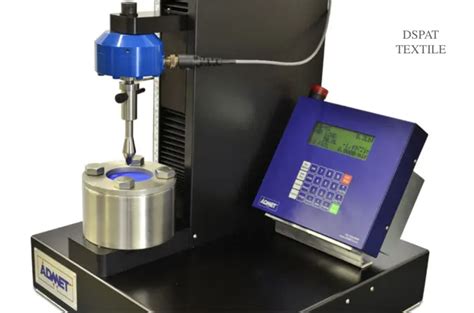

Bursting Strength Machine is used for testing fabric bursting strength and expansion such as knitted fabrics, non-woven fabrics, leather etc. Bursting Strength Machine Method: The sample is held at an extension on .

Part 1: Test bursting strength and expansion of textile fabric by hydraulic method (GB/T7742.1-2005). Textile fabric bursting properties. Part 1: Determination of bursting strength. “Mullen burst” is a type of test that assesses the strength of a fabric by using a bursting method, or determining how much force is required to rupture the fabric as it is distended. The test method used is ASTM D3786: “Standard Test Method for Bursting Strength of Textile Fabrics—Diaphragm Bursting Strength Tester Method,” and it is .

ASTM D3786 – Standard Test Method for Bursting Strength of Textile Fabrics – Diaphragm Bursting Strength Tester Method: This ASTM standard outlines the procedure for determining the bursting strength of textile fabrics using a diaphragm bursting strength tester.It is commonly used in the textile and apparel industry to evaluate the strength of fabrics.Download scientific diagram | Bursting strength test results of sample knitted fabrics from publication: Comparison of the performance and physical properties of plain, pique, double-pique and .Before testing, prepare the fabric bursting strength tester, cut the specimen as required and conditioning it for use. Select a suitable test area according to requirements. 50 cm² is suitable for most fabrics. Set the test parameters for the fabric bursting strength tester.BURSTING STRENGTH Measurement of Fabric Bursting Strength: In this test a 25mm diameter steel ball is pushed through the stretched fabric and the force required to do so is recorded. The advantage of the test is that it can be carried out on a standard univ ersal strength tester with a suitable attachment.

knitted fabric burst strength

Bursting strength is a measure widely used for knit fabrics, nonwoven fabrics, and felts where the constructions do not lend themselves to tensile tests. The two basic types of bursting tests are the inflated diaphragm method and the ball-bust method. (Shah V (1998) Handbook of plastics testing technology. This machine is used to test bursting strength in the fabric testing laboratory. It has a hydraulic system for pressure, which is either achieved by oil or glycerin. The fluid is 96% chemically pure glycerin. The hydraulic system should be free of any external vibrations. Clamps are also used to uniformly secure test samples. 5.2 In cases where test results obtained using the procedures in Test Method D3786 have not been correlated with actual performance, Test Method D3786 is considered satisfactory for acceptance testing of commercial shipments of textile fabrics for bursting strength since the method has been used extensively in the trade for acceptance testing. In .

Burst strength testing. Burst testing measures the strength of fabrics and materials, by providing pressure (force) on the material from all directions equally at the same time, to measure the conditions that will cause it to rupture. When a fabric 'fails' due to bursting, it means that the fabric has a low breaking extension.In some standards they advise to use a smaller or bigger dome. Some standards make provision of a sample not bursting. For example in ASTM D3786, it states: If the fabric does not burst, the report should state the maximum bursting pressure of the instrument and that the sample had not burst at that pressure. In conclusion, choosing the right fabric bursting strength tester requires careful consideration of factors such as the type of fabric being tested, the testing standards and requirements, the .D 3786 Test Method for Hydraulic Bursting Strength of Textile Fabrics Hydraulic Diaphragm Bursting Strength Tester Method3 3. Terminology 3.1 Definitions: 3.1.1 bursting strength, n—the distending force, which is applied at right angles to the plane of the fabric, under specific conditions, which will result in the rupture of a textile.

Burst strength test is the modern technique used to measure the strength of the fabrics and textile materials by providing the stress on the material from all the directions equally at the same time. It is widely used the testing procedure .

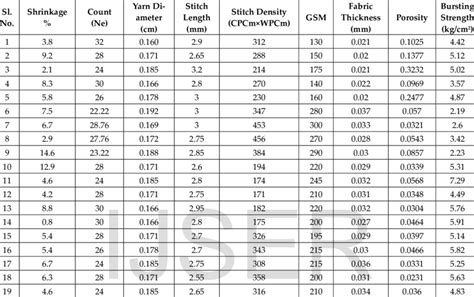

Table 3–13 Relevant domestic and international standards for testing the bursting strength of textiles. . Uncertainty analysis of knitted fabric bursting strength test;

Fabric Bursting Strength Test by Diaphragm & Ball Method; Different Types of Fabric Tearing Strength Test Method; Mazharul Islam Kiron. Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. He is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia. There are two types of Bursting Strength Test: Diaphragm Bursting Test; Ball Bursting Test; Diaphragm Bursting Test. It is a method where a fabric, which is to be tested, is held with rubber diaphragm with a help of a clamping ring and an increasing fluid pressure is applied till the specimen bursts, and the pressure required is noted. This .

ultrasonic hardness tester krautkramer

A quick video showing a burst strength test on textiles samples using the ball burst test. This test is very similar to a puncture test. For more information.The volume of fluid is increased at a constant rate per unit time until the test specimen bursts. The bursting strength and bursting distension are determined. . For most fabrics, particularly knitted fabrics, the test area of 50 cm2 is applicable. For fabrics with low extensibility (known from previous experience or preliminary testing), e.g .Application: Hydraulic Bursting Strength Tester is applied to determine the bursting strength test and distension at burst of woven, knitted and non woven fabrics, papers and boards by the application of hydraulic load under a rubber diaphragm.. Standards: ISO 13938.1, FZ/T 60019, FZ/T 01030, ASTM D3786, BS 4768, WOOLMARK TM 29WSP 30.1, JIS L 1018.6.17, SATRA .

ultrasonic hardness tester met-u1a

Determination Of Bursting Strength In Fabrics E322 Factors that are affecting the test result of fabric bursting strength A.Internal factors. 1)Yarn breaking strength and elongation of the impact. When the yarn in the fabric has high breaking . Burst strength testing is the application of a perpendicular force to a fabric until it ruptures. The force is normally applied using either a ball or a hydraulically expanded diaphragm. . When a fabric fails during a bursting strength test, it does so across the direction which has the lowest breaking extension. When a burst test is .

Key Point for Bursting Strength Test. . The procedure for measurement of the Bursting Strength of textile fabrics involves the preparation of a cylinder of the fabric under specified conditions of humidity and tension. The cylinder is then placed on an expanding apparatus and inflated until it bursts. The pressure at which the fabric bursts .

how to measure fabric burst strength

how to measure bursting strength

20 de set. de 2023 · Essa ninfetinha gostosa ficou entrando na piroca com força e ficou louca de tesão gemendo. Essa putinha safada ficou fodendo com força e ganhou muito .

bursting strength test fabric|how to measure bursting strength